There is an increasing loss which is a function of the deviation or variability from the target value of any design parameter. The alternative is that the best product has a measurement which is precisely on target. Genichi Taguchi and others have suggested that traditional two-sided tolerancing is analogous to "goal posts" in a football game: It implies that all data within those tolerances are equally acceptable. This relates to the question of whether tolerances must be extremely rigid (high confidence in 100% conformance) or whether some small percentage of being out-of-tolerance may sometimes be acceptable.Īn alternative view of tolerances The choice of tolerances is also affected by the intended statistical sampling plan and its characteristics such as the Acceptable Quality Level. A process capability index is used to indicate the relationship between tolerances and actual measured production. Process controls must be in place and an effective Quality management system, such as Total Quality Management, needs to keep actual production within the desired tolerances. The process capability of systems, materials, and products needs to be compatible with the specified engineering tolerances.

Appreciable portions of one (or both) tails might extend beyond the specified tolerance.

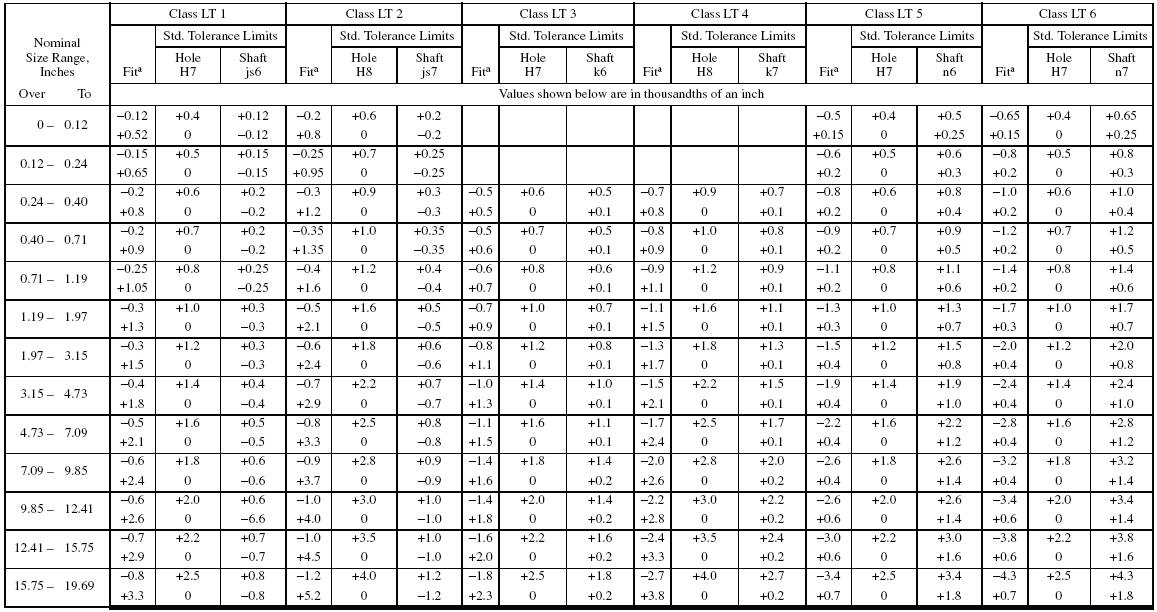

Standard tolerance chart plus#

With a normal distribution, the tails of measured values may extend well beyond plus and minus three standard deviations from the process average. Measurement error and statistical uncertainty are also present in all measurements. Actual production of any product (or operation of any system) involves some inherent variation of input and output. Experimental investigation is very useful to investigate the effects of tolerances: Design of experiments, formal engineering evaluations, etc.Ī good set of engineering tolerances in a specification, by itself, does not imply that compliance with those tolerances will be achieved.

Standard tolerance chart professional#

This can be by the use of scientific principles, engineering knowledge, and professional experience. 5 Difference between allowance and toleranceĬonsiderations when setting tolerances Ī primary concern is to determine how wide the tolerances may be without affecting other factors or the outcome of a process.1 Considerations when setting tolerances.

0 kommentar(er)

0 kommentar(er)